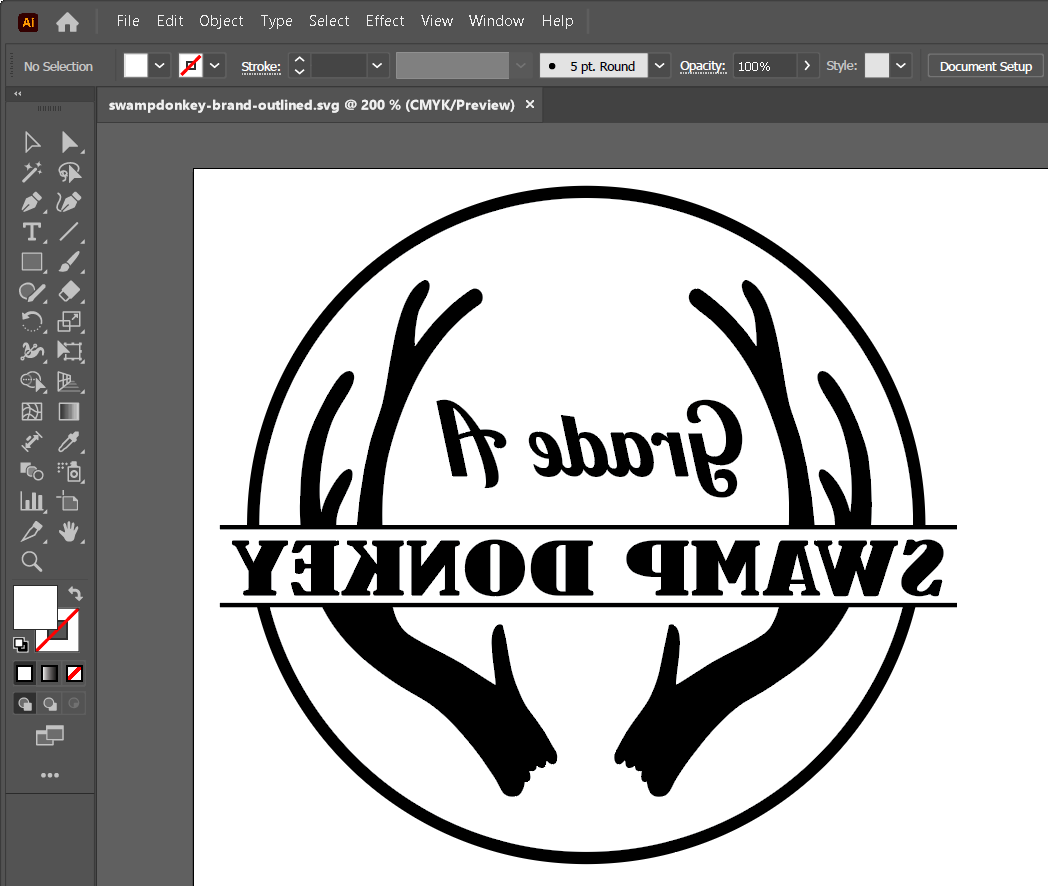

Teresa came to Maker Works in 2021, eager to learn what it had to offer. She took classes across multiple areas (mainly woodworking, laser cutting, resin printing, and plasma cutting), turning her skills into a stream of creative projects. She steadily expanded her knowledge while also giving back to the Maker Works community by volunteering at events. Over time, Teresa developed a strong foundation in digital design and fabrication, setting the stage for this next project: a custom brass food brand as a gift for a friend. (What does the text on it mean? We don’t really know!)

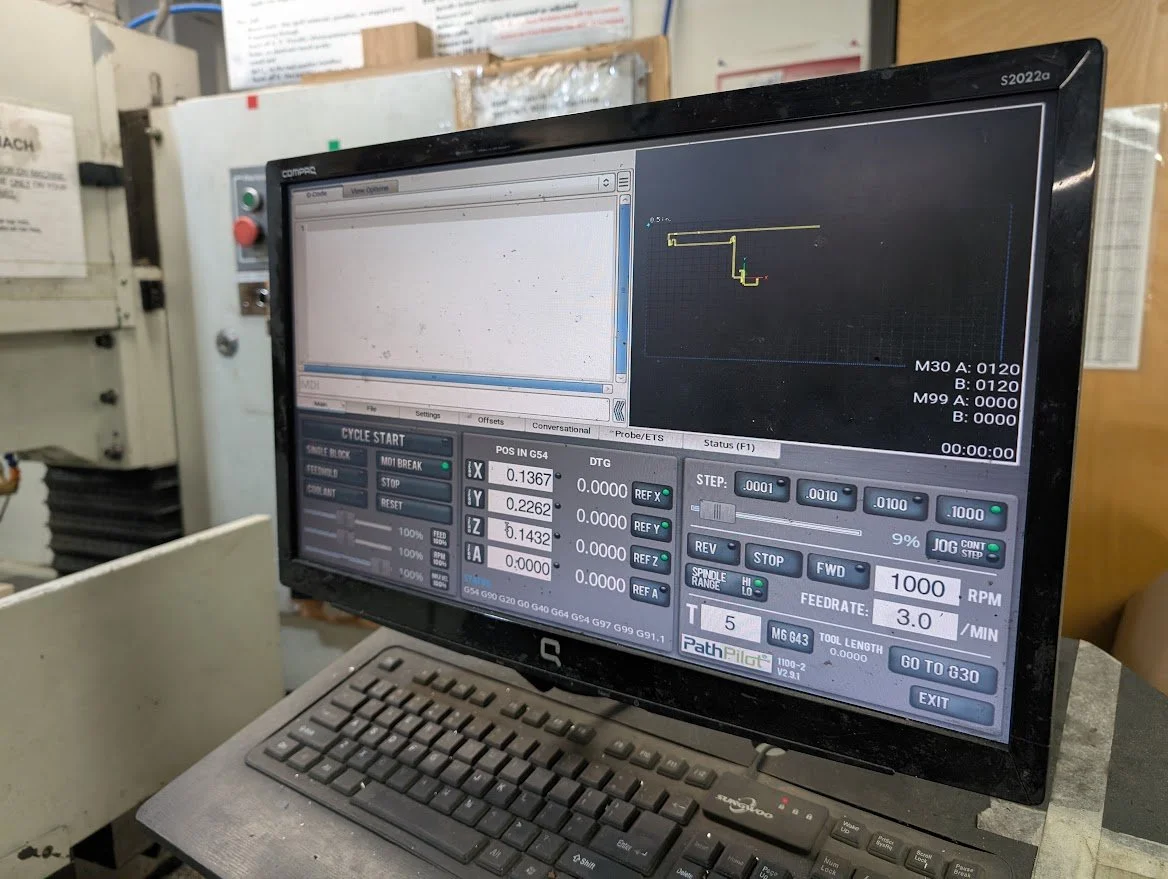

With an Adobe Illustrator file in hand, Teresa approached the Maker Works staff to determine the best way to bring her design to life. Given the precision required, they identified the Tormach CNC mill as the ideal tool. However, with limited time to learn all the necessary steps herself (it was the holiday season, after all), she opted for private consulting to accelerate the process. Working alongside another shop member who offered to help, she learned how to import her design into Fusion 360, extrude it into a 3D model, and create CAM toolpaths to generate the G-code needed for the Tormach.

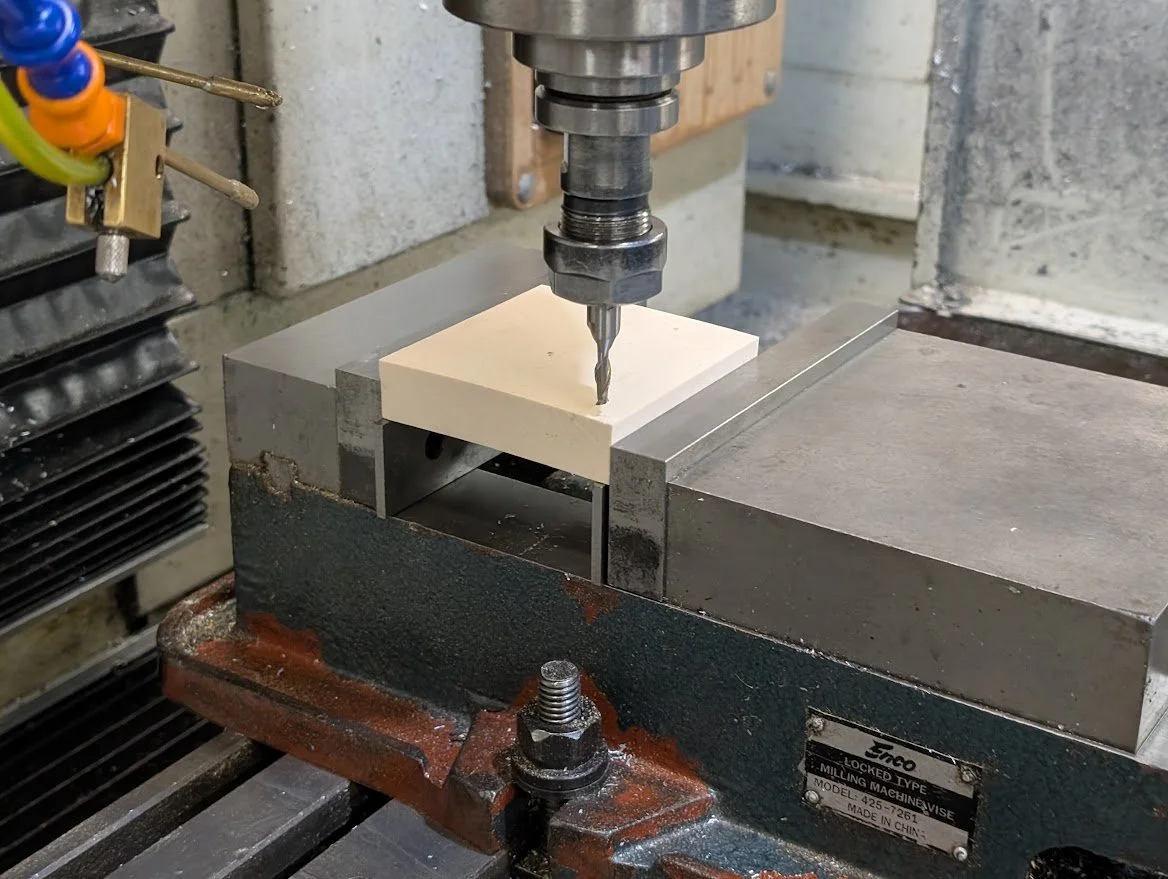

Once confident in the software setup, Teresa had help facing her brass blank on the Clausing metal lathe. They only had two brass blanks available… so, just to play it safe, they found some scrap tooling board to create the first prototype.

Doing a prototype with the tooling board helped Teresa see that all of the toolpaths were correct, so that meant it was time to move to the real material: brass!

The first attempt didn’t go perfectly. But with adjustments and persistence, the second try worked beautifully, and the brass plate was milled in less than 2 hours. After a bit of deburring on the belt sander, it was ready to become a food brand!

A big appreciation to Al, Dale, and Nova for helping make this happen. Thank you Teresa for letting us share your work and all your help supporting the shop!

Ingredients

Brass stock, purchased from Alro Metals Outlet (Ann Arbor)

3/16”, 1/8”, and 1/16” flat end mills

1/8” 15° D-bit