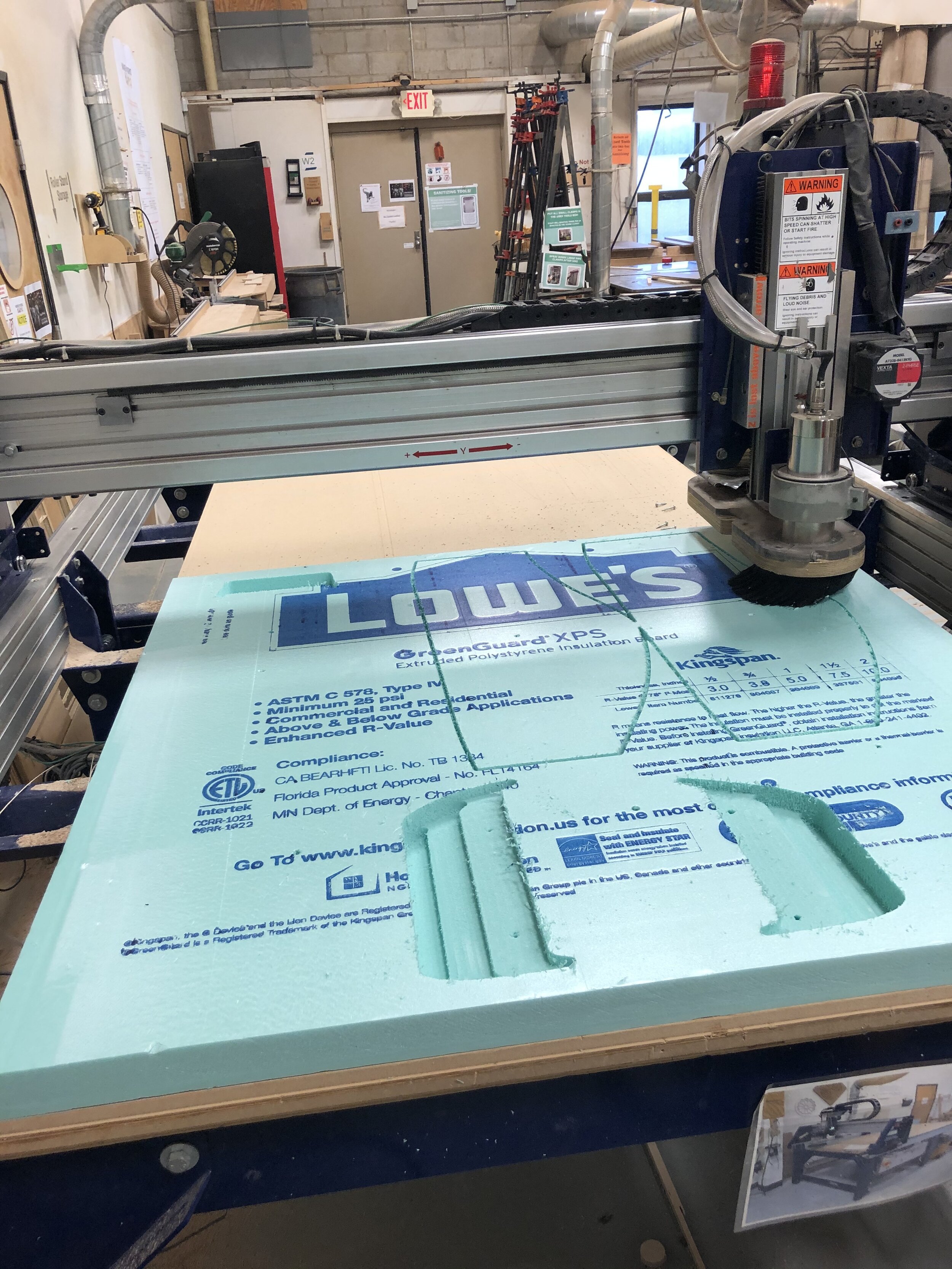

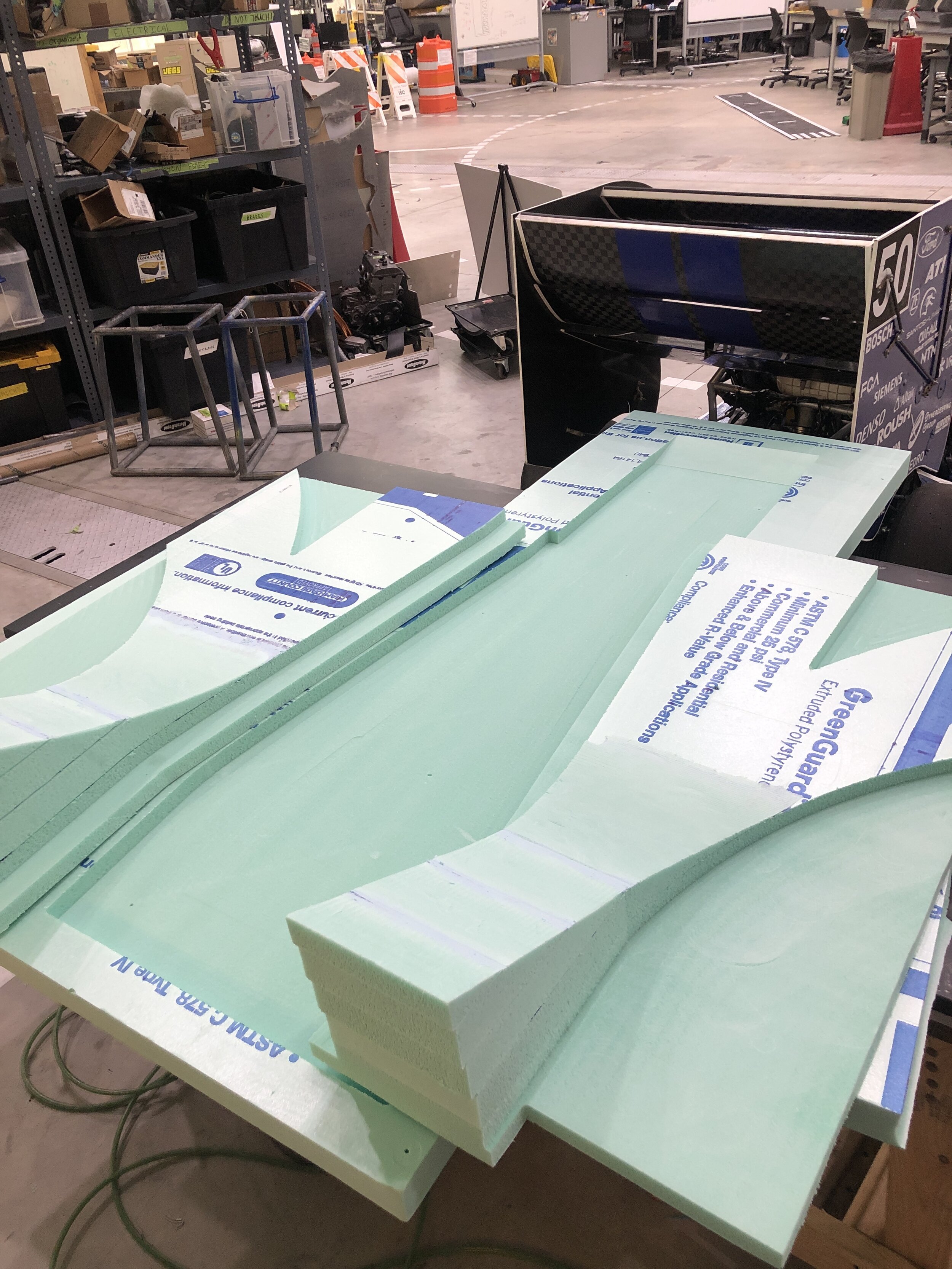

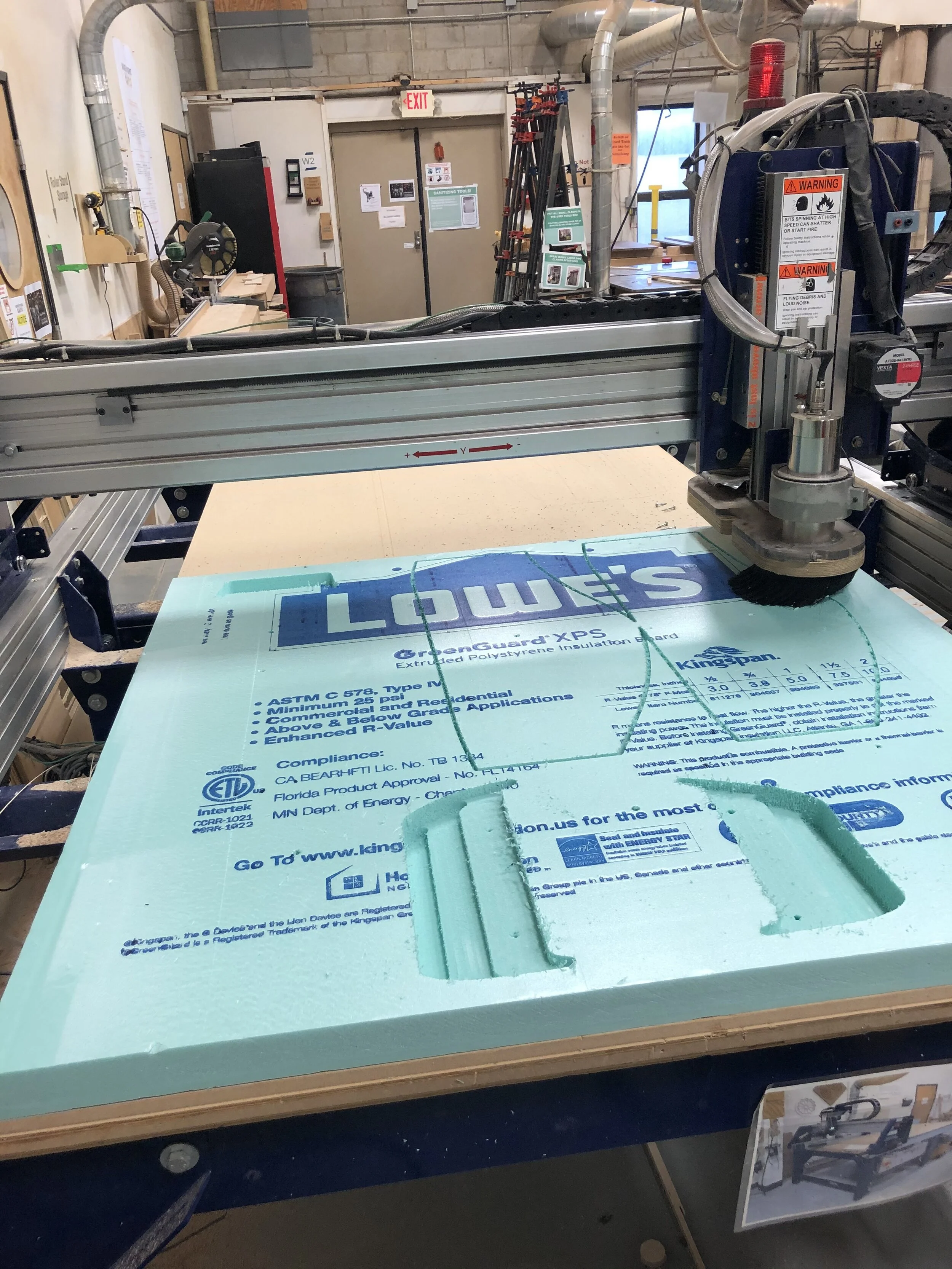

Maker Works member Tyler Makowski is the aerodynamics lead on the University of Michigan-Dearborn's Formula SAE Racing Team. The team is composed of UM-D students (mostly engineering) who design, build, and test a Formula 1 style race car and compete against other schools each year (except 2020, due to COVID). He uses the ShopBot to create the foam molds used to fabricate carbon fiber body panels for the car:

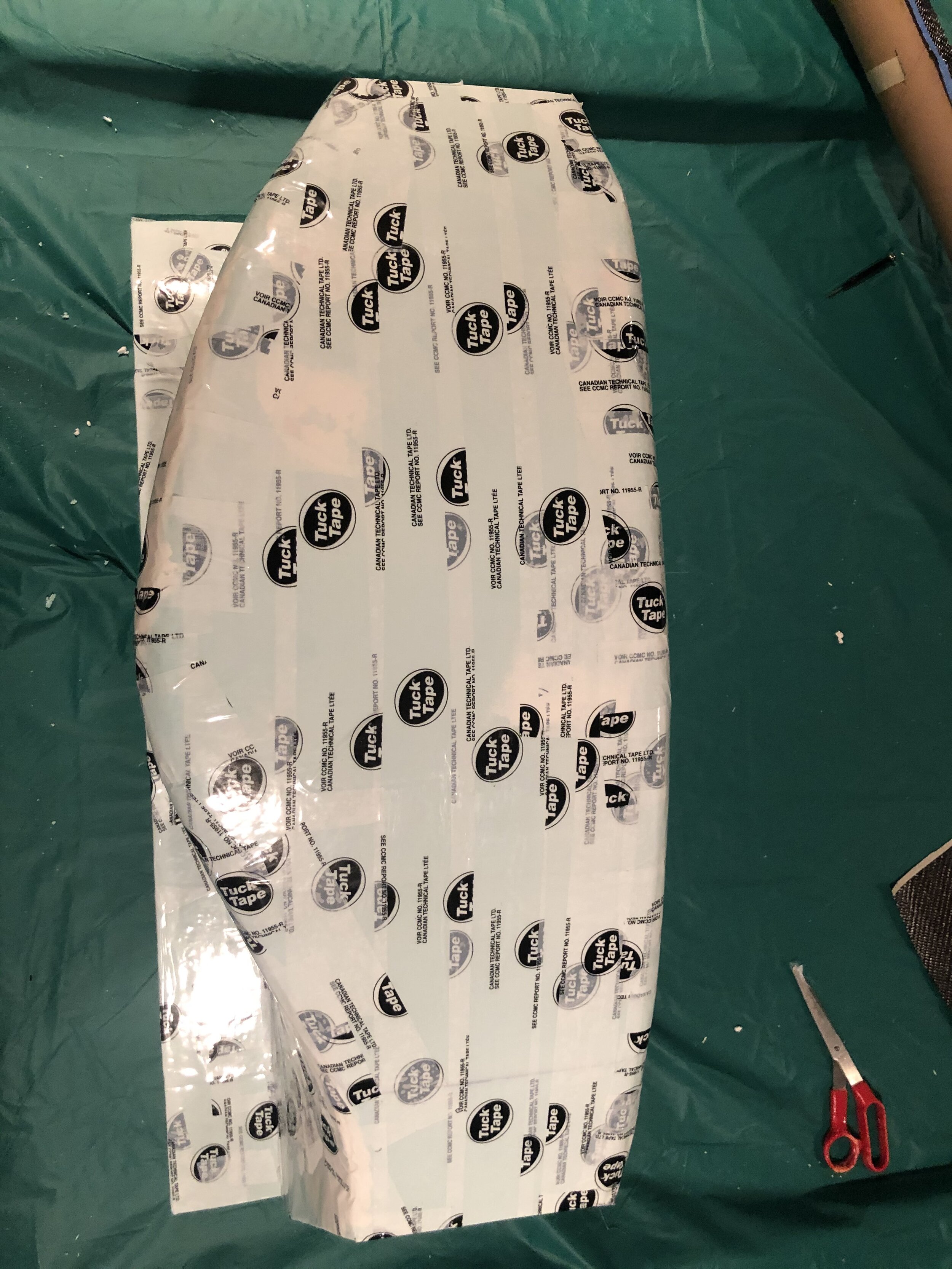

Body Panel/Mold - A foam mold to create each of the carbon fiber body panels. The 2020 car has a total of 6 body panels.

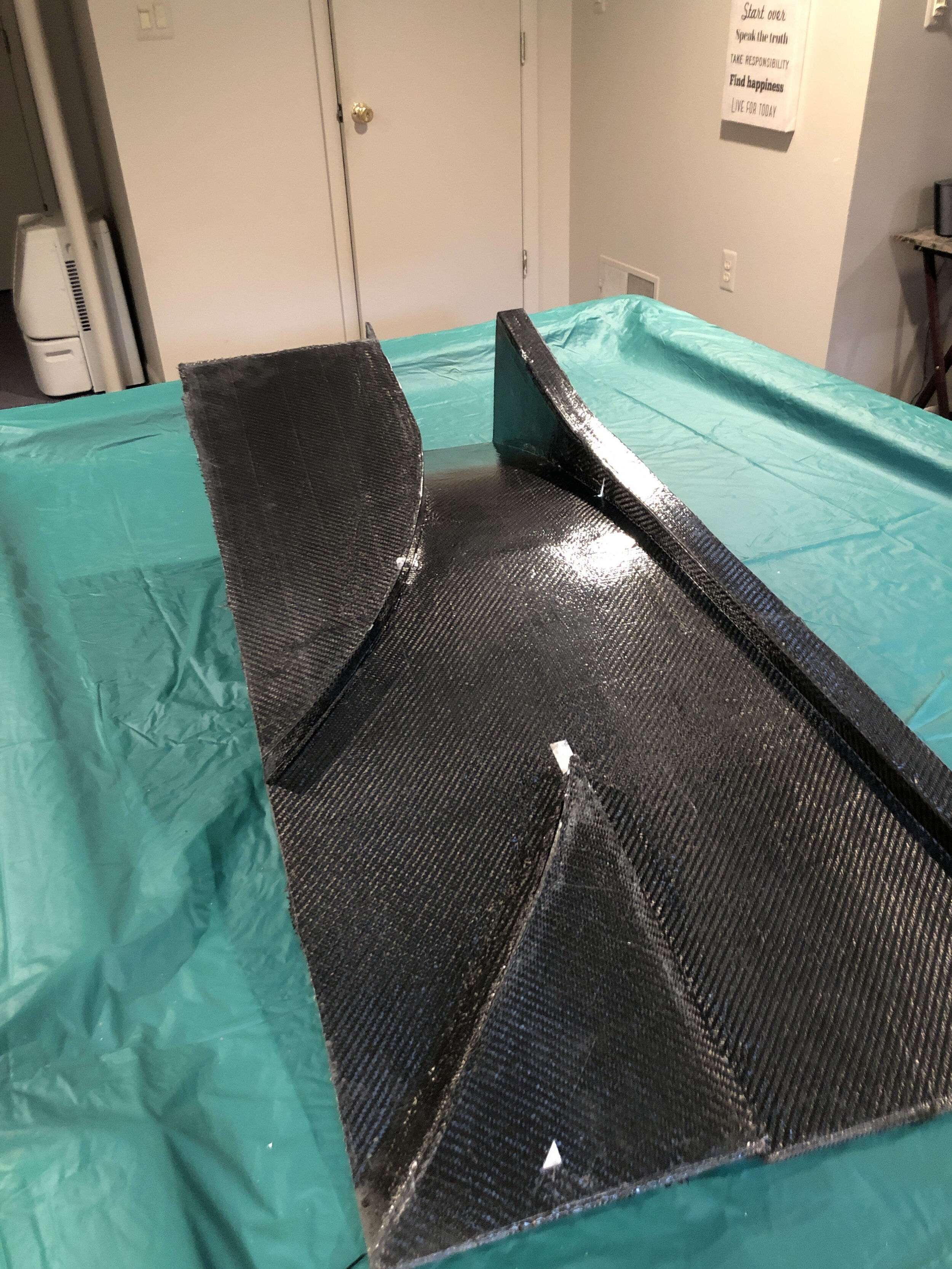

Undertray/Diffuser - The carbon fiber part is placed underneath the car and allows for clean airflow increasing the cars stability when making sharp turns.

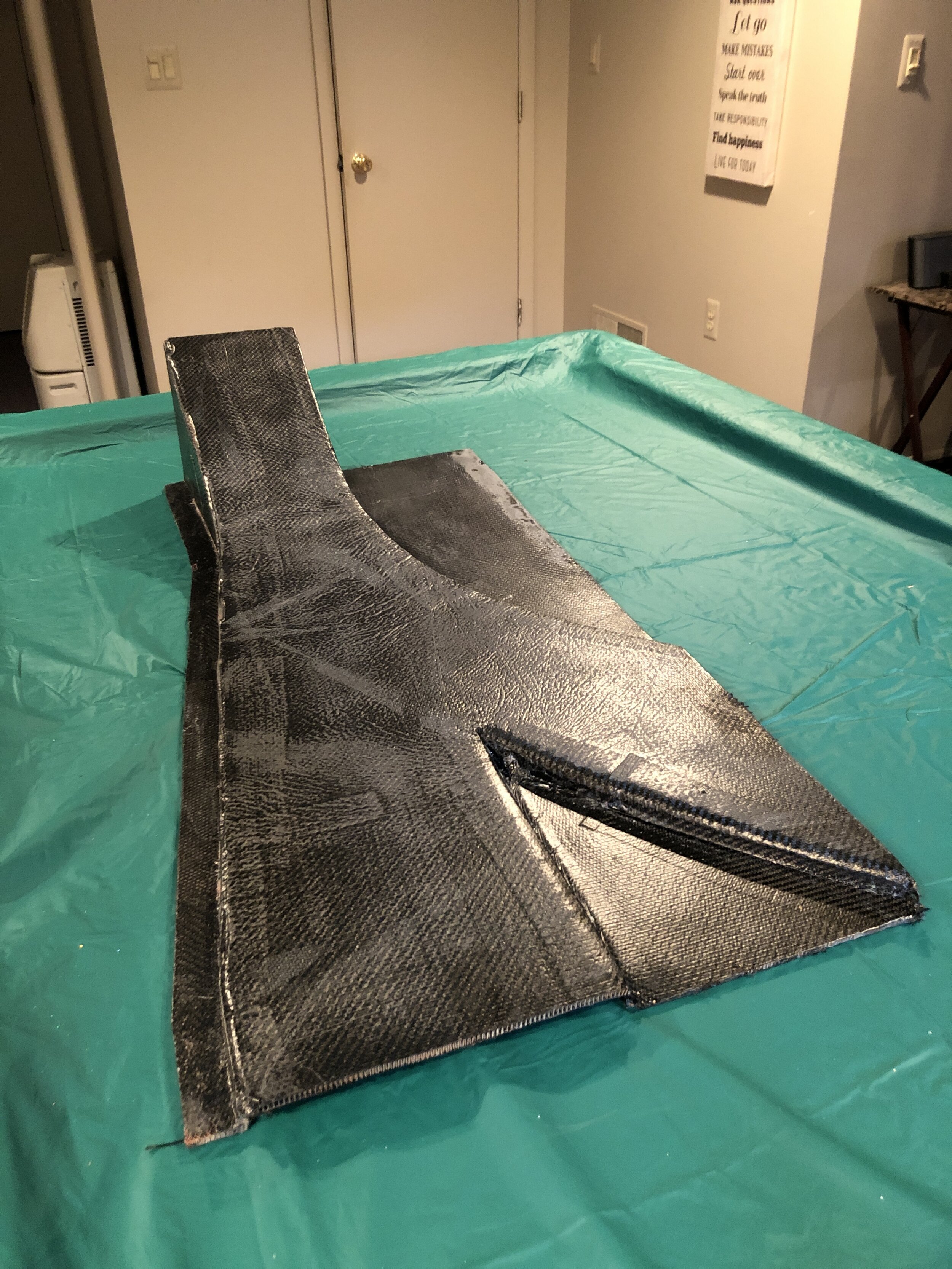

Side Pod - This carbon fiber part houses the radiator.

Dashboard - This Carbon fiber part houses the LED dashboard and additional switches and controls.